Wheel Manufacturing and Construction

Lately I've been asked, "What is the difference between a $3000 set of wheels and a $500 set of wheels? First it's important to understand that not all wheels are made the same. These are the manufacturing techniques that make those $3000 wheels cost that much.

Gravity Casting

This is the most basic process of casting wheels. You're pouring molten aluminum into the mold and using gravity to fill it. Production costs for Gravity casing is very affordable. This is a great method for producing wheels that are more visually oriented and when reducing weight is not important. Because gravity does not offer much force in molding the product formed is not densely packed. This leads to a higher wheel weight.

Low-Pressure Casting

Low pressure casting is very similar to the process of gravity casting. But instead of letting gravity do the work, low pressure is applied to the molten aluminum. This pressure moves the aluminum into the mold quicker, thus producing a wheel that has a higher density that that of a gravity-cast wheel. Do to the slightly higher production cost, low-pressure cast wheels will have higher prices in the retail markets. Low-pressure cast wheels are one of your best bang for your buck wheel options. They''re a great value when it comes to a quality wheel with good strength and a little lighter weight. Examples of this process is Avid, Cosmis, Option Lab and Rota.

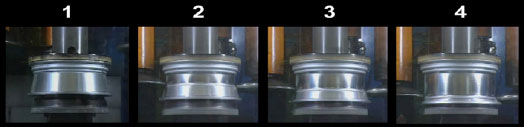

Spun-Rim, Flow-Forming, Rim-Rolling Technology

This is a process that starts with a low-pressure cast wheel. Once the wheel has been created it goes onto a special machine that will evenly heat up the outside of the rims and steel rollers are used to push and pull on the rim to get the wheel to it's desired width and shape. Imagine a piece of clay on a spinning wheel. That dense piece of clay is molded while spinning to the shape and dimensions that it needs to become. This process creates a lightweight and strong wheel at a reasonable price. Examples of this process is BBS, Enkei, Konig, SSR, Gram Lights.

Forged

Forged wheels are the pinnacle in one-piece wheels. The forging process uses high temperature and pressure to change the structure of the billet aluminum block. Once the forged block resembles the shape of a wheel. It is put into a CNC machine where the spokes and hub design are made. This process creates a very strong and very light wheel. Because of the costs of design, equipment and tooling, these wheels at priced at a premium and are typically top dollar. Examples of these is Volk Racing.

Multi-Piece Wheels

These wheels are the result of two or three wheel components (hubs, spokes and rims) assembled together to create a wheel. Each piece can use a different manufacturing processes. Hubs can be cast or forged, etc. These wheels can cost even more than that of forged because of the work that goes into each of the processes and wheel components.